Roll Coaters

Always read machine instructions and never touch a moving or energized roll.

Roll coaters sit at the heart of the galvanizing or painting process for metal strip. Your safety, productivity, yields, and coating consumption depend on them being built well. Existing lines have special challenges with limited space, limited downtime, and short production ramp ups.

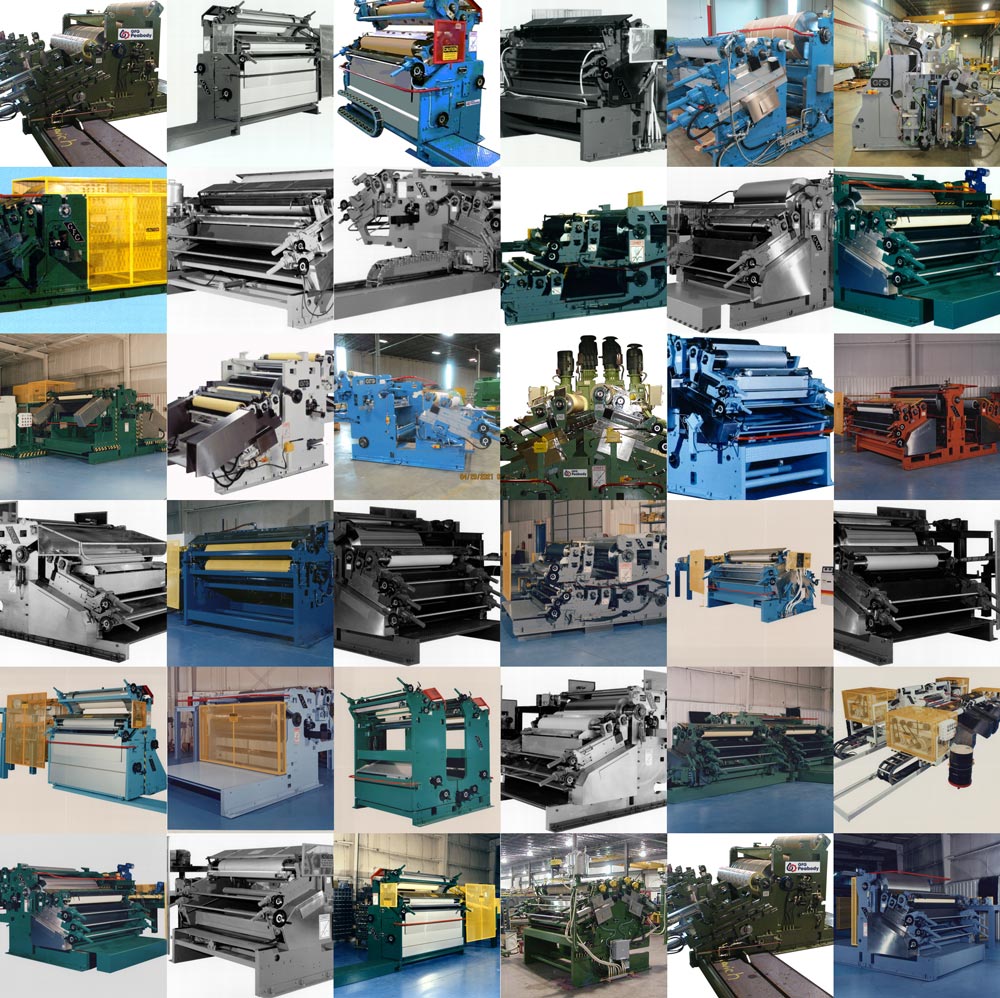

GFG Peabody’s custom-built roll coaters can apply paint, chemical treatments, or wax to metallic strip in the range of thicknesses and widths that you coat. Rolls of a specific material, texture, and size precisely meter and apply the coating smoother, with less waste and better control than spraying. Such a consistent and thin application of a treatment or coating allows material to be chemically treated, wax coated, applied with adhesive or painted to specification. Dependable, innovative, and built to last, our roll coaters can take your coil processing line to the next level.

These coaters are made to fit an existing line or be installed in a new coil processing line by the overall line supplier with ease. GFG Peabody can work with you to get the right features and fit to get your coating right.

Types of Roll Coaters

Some of GFG Peabody's Roll Coater applications

- Chemical coaters coating for Galvanizing Lines

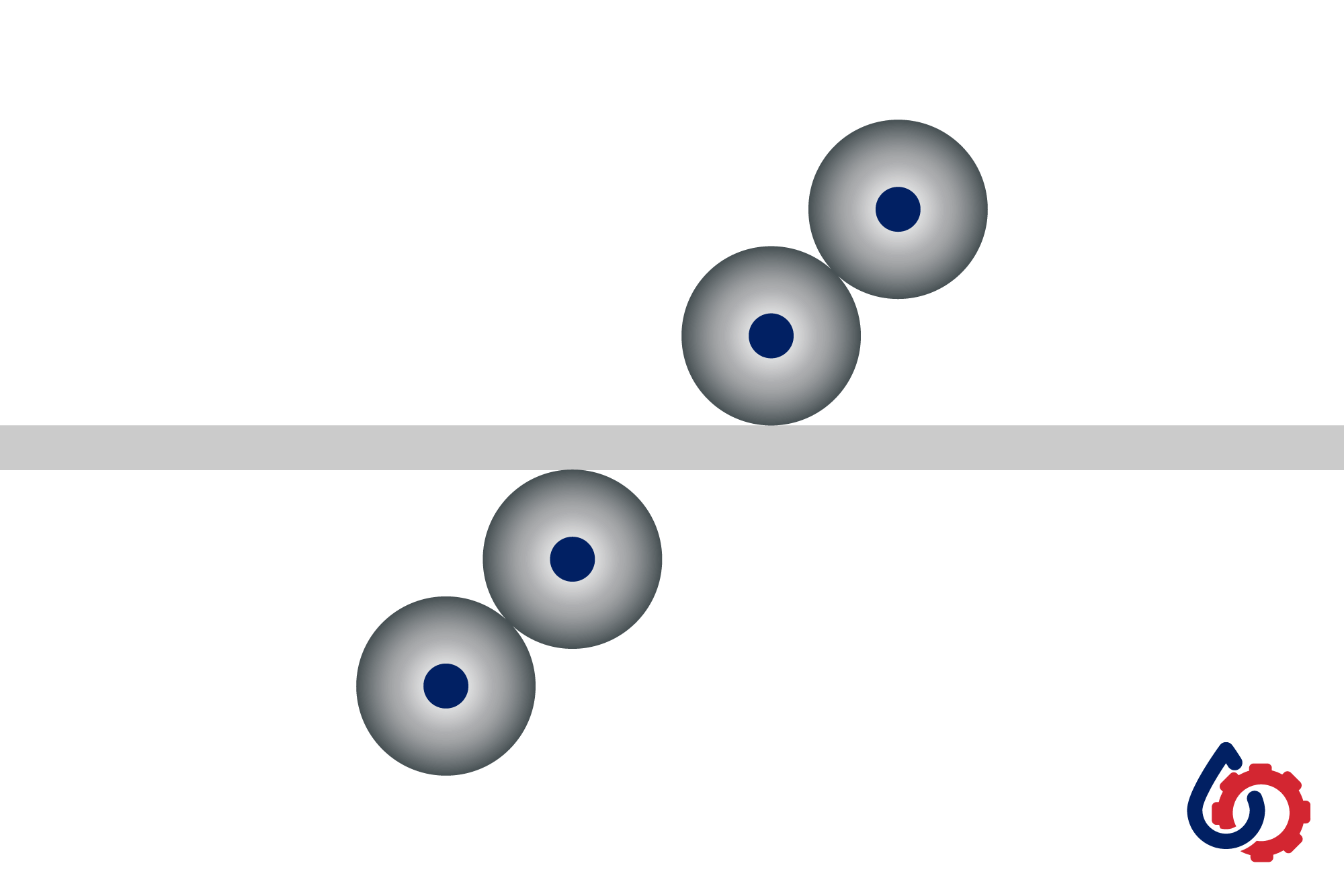

- Horizontal

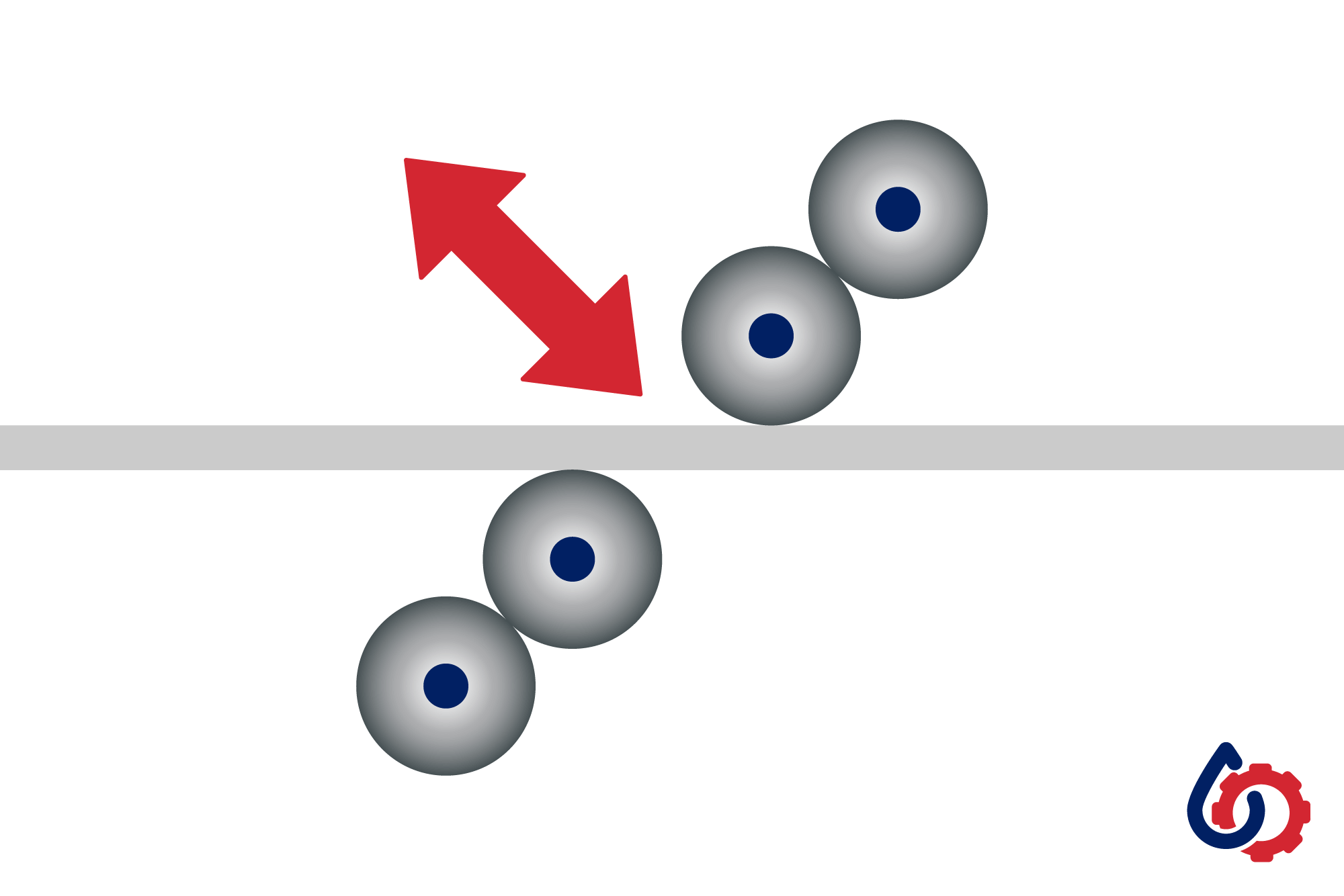

- Clamshell

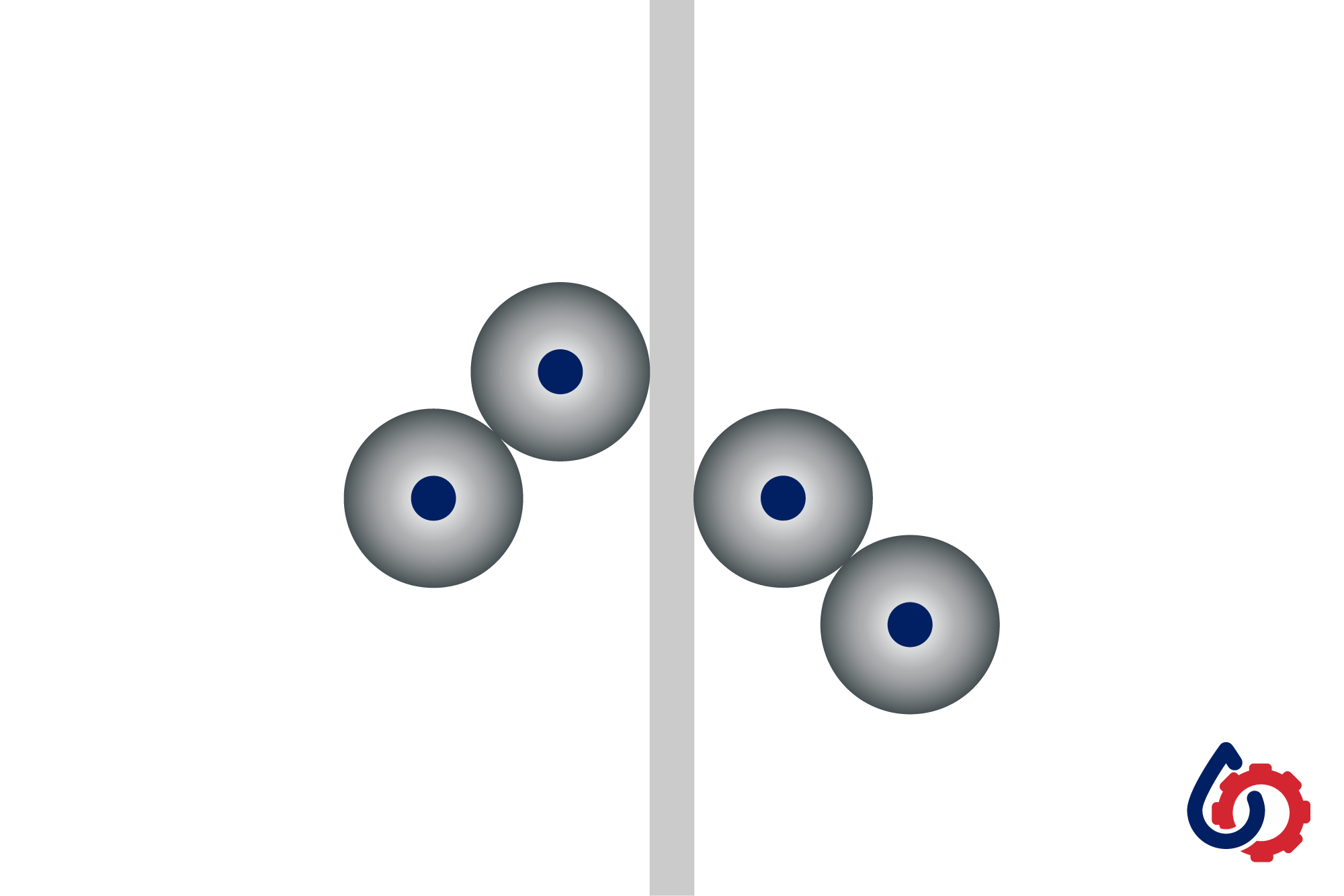

- Vertical

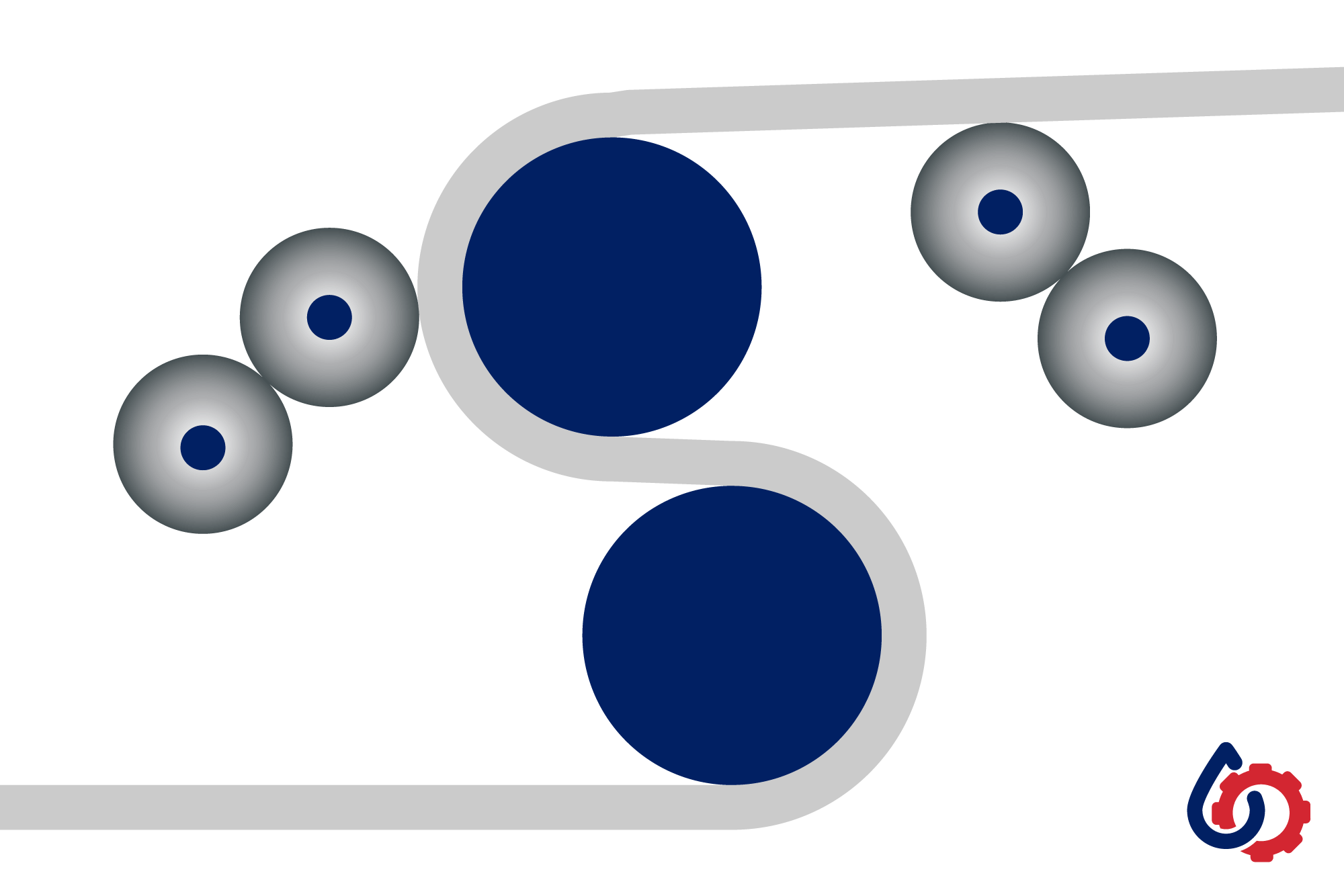

- S Wrap

- Quick Change

- Prime Coaters for applying primer paint to top and bottom side.

- Finish Coaters (S-Style, T-Style, Quick Change)

- Vertical Wax Coaters for applying dry film lubricants and food grade coatings.

Over

50 countries since 1969.

We make our equipment to fit your space and meet your needs. Each machine is unique and engineered to order.

Challenge us with your requirements

You will be surprised!