Advantages of Electrostatic Spray

An electrostatic spray application is advantageous versus a traditional application method. The spray quality is much higher utilizing the electrostatic application.

Electrostatically sprayed material contains smaller charged particles that have a higher attraction to a grounded surface, and as a result, less over-sprayed material is wasted. The smaller size of particles contributes to a finer coated surface. Also, the charged material has a higher tension that makes it difficult to remove from a coated surface.

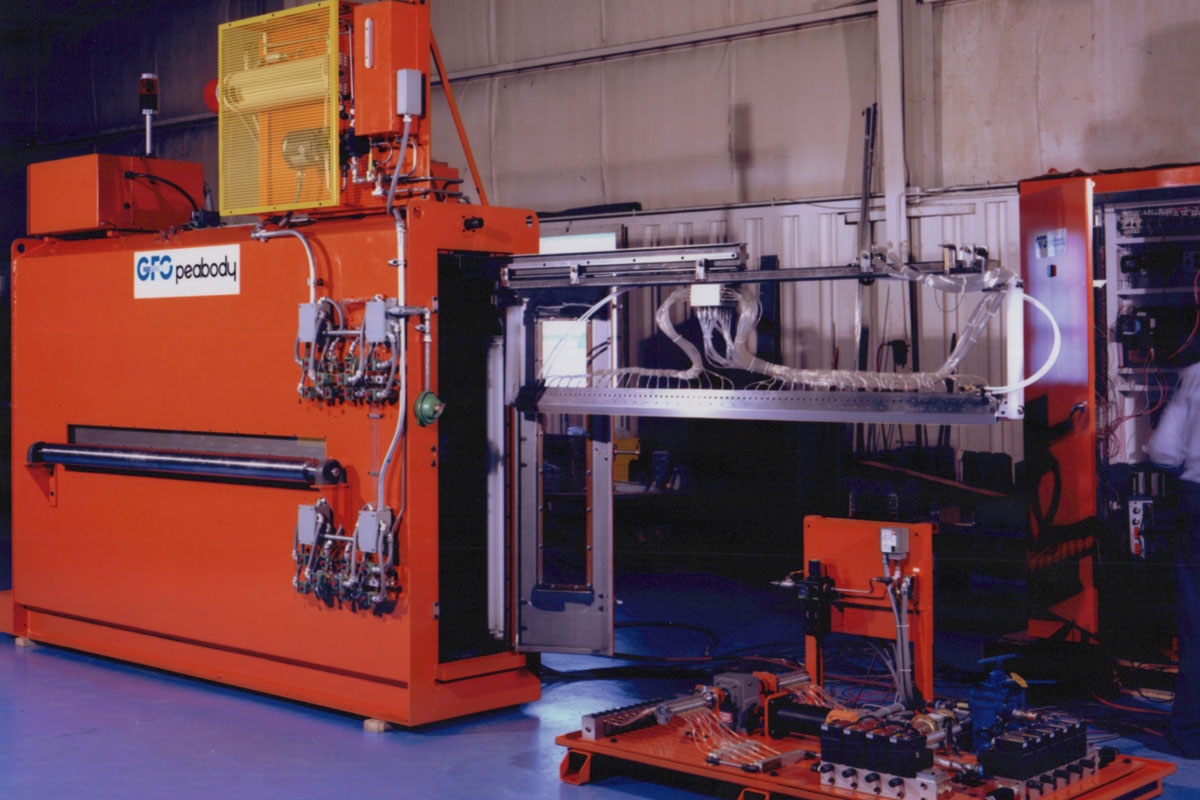

The electrostatic oiling machines are equipped with a high voltage power supplies and oil applicators that are connected to each other with a high voltage cable.

The strip processing industry mainly utilizes two types of electrostatic oil applicators: “spray blade oiler” and “rotary atomizer oiler”. Even though the main principle of electrostatics is the same there are a few differences between applications.

SPRAY BLADE OILER

The spray blade oiler utilizes stationary mounted devices called “blades”. Each blade constructed so it could deliver evenly distributed coating material to an edge of the blade and with electrostatic force sent the coating material to a nearest grounded surface (strip). The spray process does not require oil pressure instead uses an electrostatic field exclusively. The application can be performed in any direction (up, down, or sideways).

ROTARY ATOMIZER OILER

The rotary atomizer oiler utilizes an air turbine that is equipped with a spray bell. The coating material is delivered to an edge of a spinning bell and a centrifugal force breaks it down into small droplets, at the same time by applying a high voltage to the rotary atomizer the oil droplets divide into even smaller particles which creates a mist. The spray mist being electrostatically charged attracts to the nearest grounded surface (strip). The spray process does not require oil pressure instead uses an electrostatic field exclusively. The application can be performed in any direction (up, down, or sideways).