GFG Peabody是全球领先的板材涂覆设备制造商,提供成套、技术领先的非标定制设备,引领行业发展的前沿,超越您的预期。 我们追求以精益求精、 严谨科学的态度设计制造设备, 致力于为您提供性能卓绝的设备.

向您的供应商询问他们是否能提供GFG-Peabody的设备。 我们与所有板材加工线供应商合作,将我们的设备整合到他们的整体设计中,以便您在新的生产线上获得最具创新性、最安全和性能最优越的涂覆设备。

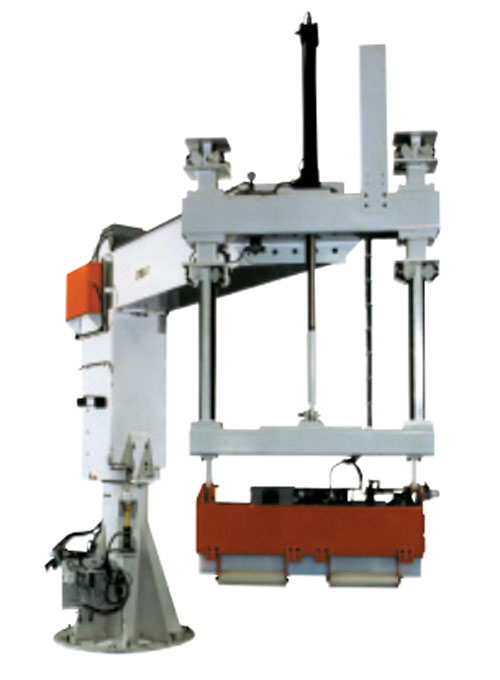

GFG Peabody涂头控制系统是一项先进的技术,显著提升了涂头的控制水平。

CHCS专为 板卷加工商设计,以满足高速工艺、严格的质量控制规范和/或需要多次涂覆设置的需求, 远远超过手动调整的水平。 CHCS能够减少废料,提高涂覆的一致性和准确性。 标准的齿 轮箱头调整被高速伺服控制的辊定位功能所取代,从而实现更高的精度、更快速、可重复 的涂覆设置,以及对涂覆过程的持续反馈和监控。

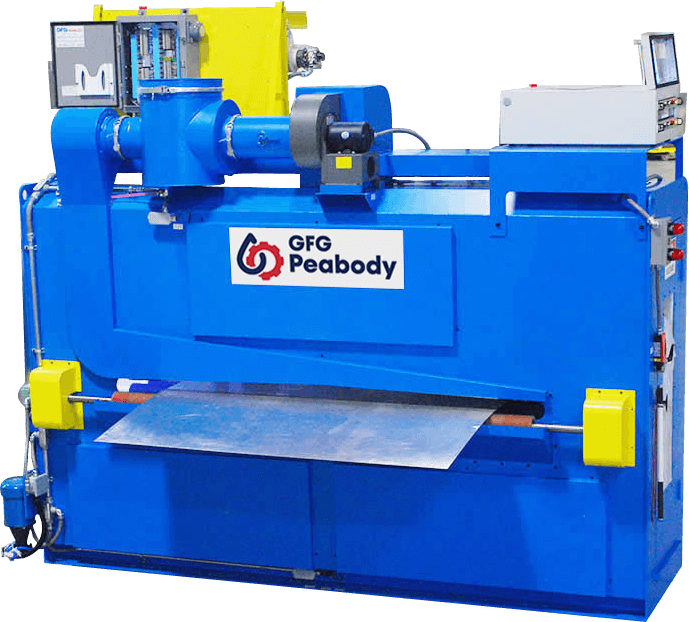

当需要在板带顶部和底部均匀而轻薄地涂覆蜡以实现加工润滑时,可以采用GFG Peabody 干油静电涂油机。

静电涂油机利用静电力涂蜡,不会因气体或流体加压导致过量涂油、漏涂油或者浪费。 蜡 通过专门的设备储存和输送。 我们的设备能以极高的精度涂覆不同参数的蜡。

在平整机组和类似的生产线上,通常并非总是有足够的空间来安装静电涂油机。 为解决这一问题,Peabody研发并成功安装了大量的“平整机”涂油机。

通过采用GFG-Peabody的涂油宽度可调刀梁设计、自动高度补偿软硬件以及专利的GFG Peabody动态电压控制等特性,我们的涂油机将为您提供在传统涂油机无法安装的情况下的终极涂油解决方案。

让我们知道我们如何可以帮助您! 在线联系我们或致电86 010-8468246。

吉森钢联冶金设备(北京)有限公司

北京市朝阳区新源里16号琨莎中心1座0910室

N53 W24900 S. Corporate Cir.

Sussex, WI 53089

View on Google Maps

© 2025 GFG Peabody | Privacy Policy

Website by LimeGlow Design