How We Work

Your new GFG Peabody equipment will be essential to your success for many years to come. We know it can’t just be picked from a catalog or an afterthought of your process line design. We have dedicated experienced professionals and specific project phases focused on quickly getting you the machine that best suits your needs.

Specify

Approve

Design

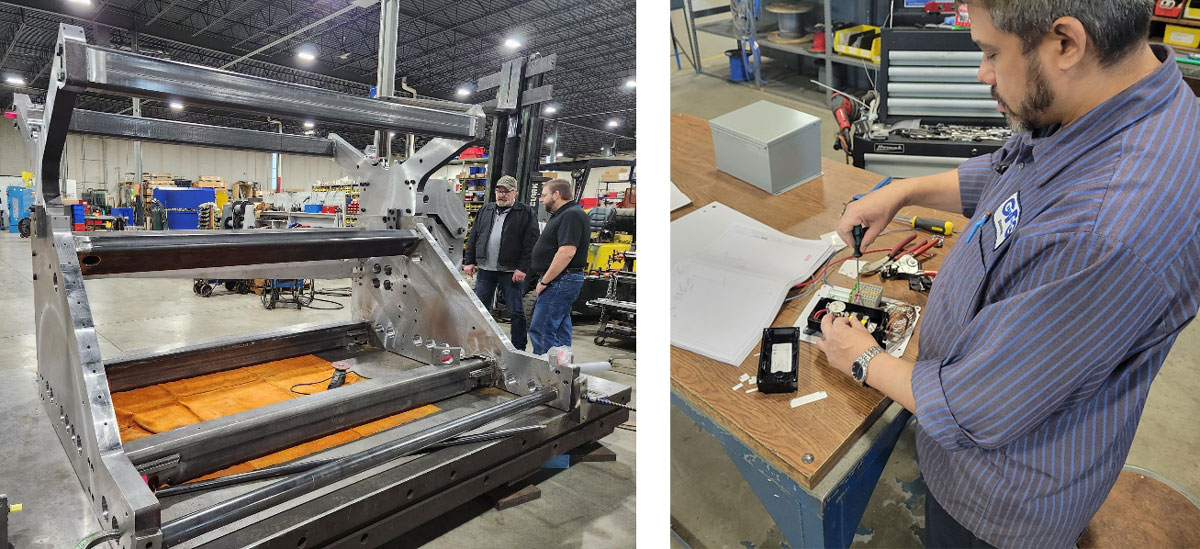

Manufacture

Testing

Shipment

Spare Parts

Installation

Startup

Specify & Propose

Our sales team will talk you through your needs in terms of speeds, coatings, integration, and space. From this information they will develop an initial configuration and price that highlights the style of machine proposed and the features you selected. This process will involve creating and revising a proposal for a machine that will form the initial basis of design.

Approve

Before we begin the detailed design and engineering, an approval phase will be a chance to layout the machine in the space available and finalize the interfaces of the machine with the plant. Mechanical and electrical drawings and schematics will be prepared by our team “For Approval” These should be carefully reviewed for feedback on utility connections, network signals and arrangement onsite of various components. At the end of this stage GFG Peabody will have enough information to proceed with detailed design and manufacture of your equipment. At the same time, you will have information you need to make your site ready for your new equipment.

Design

This is when our team starts to really design and engineer all the details that go into making sure your machine is exactly the one you want. Mechanical components, hydraulic systems, pneumatic systems electrical components, software and control panels are all design in complete detail to ensure that everything will work together.

Testing

Before shipping, the machine is connected and powered for a variety of tests. All connections are checked. Every function that can be practically replicated are tested in manual and automatic modes of operation. Although it is not required, we find a much higher degree of success when customers participate in this stage in person.

Spare Parts

Spare parts can be purchased at any time. We recommend purchasing an initial set of spare parts with your order. Some parts may have to wait to be purchased after design. In these cases, you can wait to order all your spares as one package at that time or issue a second order for those spares that we are unable to specify at the time of machine purchase.

Installation

We will provide ample documentation for the installation of your equipment. If an onsite installation adviser is required, contact our Service and Parts team.

Commissioning / Start-up / Training

Onsite technicians can be made available for all variety of services during the first operation and ramp up period of your new machine. These services may also be purchased at any time, but we recommend submitting your order for commissioning time when you buy the machine.